CYKEO-T3 Wall-Mounted RFID Gate Reader

1317Cykeo CYKEO-T3 industrial RFID gate reader features 200cm detection, infrared triggering, and dual alarm modes for warehouses/libraries. Supports WiFi/4G and Java/C# SDK integration.

MoreAll RFID Product

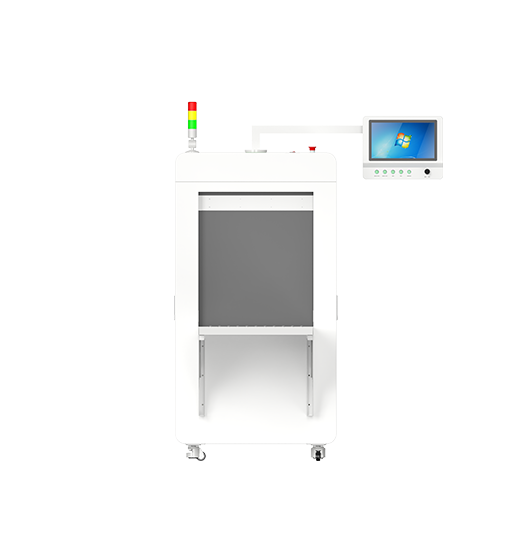

CK-TP2D

Semi-Automated Verification Solution for Mid-Scale Warehouse Operations

✔️ Enclosed reading chamber with shutter door

✔️ Infrared-triggered conveyor system

✔️ 14-inch touchscreen showing real-time data

The CK-TP2D is a compact RFID tunnel scanner with a shuttered chamber and infrared conveyor for accurate batch scans. 14-inch touchscreen makes check-in/out easy and fast.

Great for small warehouses, retail backrooms, or tool/equipment storage handling medium cartons or stacked items.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

The closed chamber blocks outside RF noise and ignores nearby tags. Inside, antennas focus on the item, no matter its position. The door and scan are automated, so reading happens at exactly the right moment—no misses, no guesswork.

Safety’s built in all around. The shutter has an anti-pinch sensor to stop if something’s in the way. Item sensors and smart logic make sure the door and conveyor only run when everything’s in place. Emergency stop buttons and a manual override give full control when needed.

It plugs into your WMS via API or network, pushing scan data in real time. Every item logs its tag, time, scan status, and any mismatches. The touchscreen shows live results, and all transactions are saved for audits, efficiency checks, or spotting recurring issues.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.

Cykeo CYKEO-T3 industrial RFID gate reader features 200cm detection, infrared triggering, and dual alarm modes for warehouses/libraries. Supports WiFi/4G and Java/C# SDK integration.

MoreCykeo's RFID scrub return cabinet offers 50-gown batch scanning, HL7 integration, UV decontamination, and JCAHO compliance for hospitals/surgical centers.

MoreCykeo's CK-DP6B library kiosk features UHF RFID tags reader technology, 21.5" touchscreen, and Windows/Android OS for 24/7 book circulation. Achieves 99.9% inventory accuracy with ISO 18000-6C compliance.

MoreCYKEO CK-M16 RFID Module is a 16-port UHF RFID reader module based on the R2000 chipset. Designed for dense tag environments, it supports ISO and GB standards and delivers stable multi-antenna control for industrial automation.

More