Submit your request to us

We will contact you as soon as possible.

All RFID Product

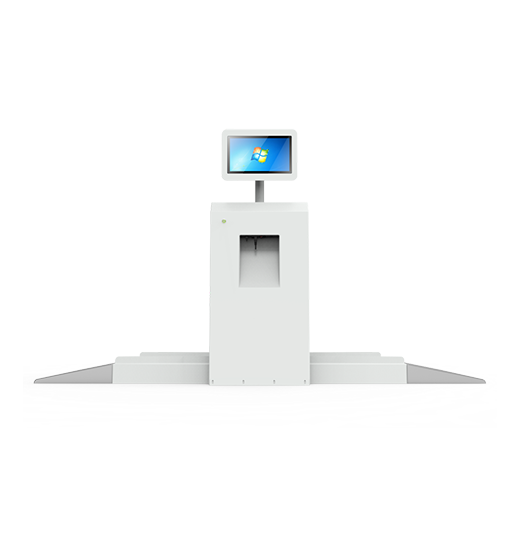

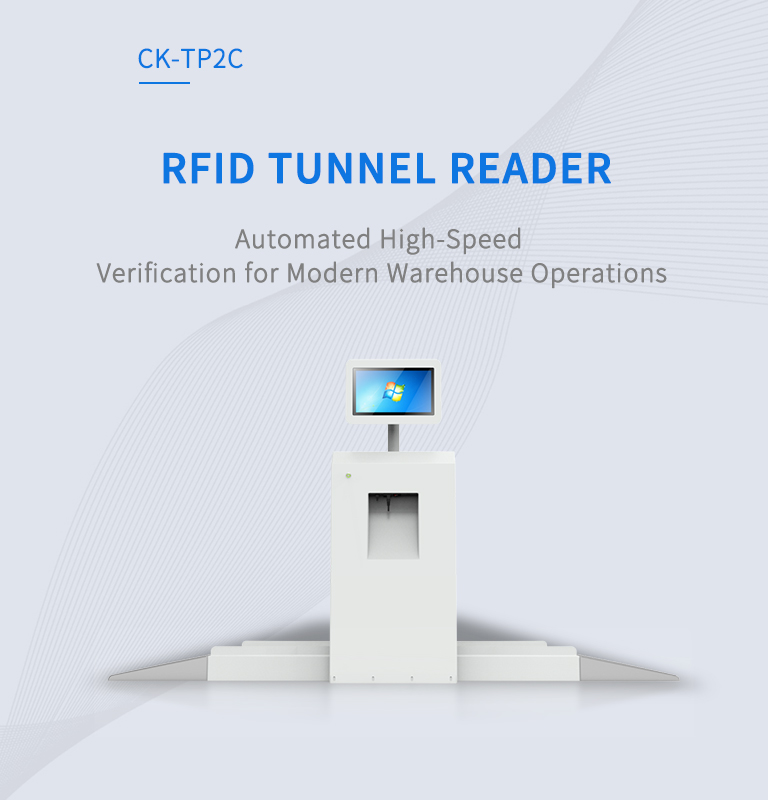

CK-TP2C

Automated High-Speed Verification for Modern Warehouse Operations

✔️ 400+ Items Identification in 3 Seconds

✔️ 4-Antenna Array with 11dBi Narrow Beam

✔️ PLC-Controlled Conveyor System

The CK-TP2C RFID Tunnel Reader is basically a fast, no-nonsense verification machine for busy warehouses. The 4-antenna UHF setup and PLC-driven conveyor blast through about 400 items in a few seconds, and the 14″ screen shows everything as it happens—good reads, mistakes, whatever. It works with Windows or Android, drops straight into your existing workflow, and takes inventory accuracy to pretty much 99.9% without the labor headaches.

Perfect for spots that move a lot of stuff every day—distribution centers, parts warehouses, book hubs, medical supply stations—anywhere you need quick, reliable item checks without slowing things down.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

It shoots the RF energy in a tighter zone, so you don’t pick up random tags on the side. With four angles hitting the box, there’re basically no dead spots—tags read clean even if they’re buried or turned weird.

PLCs are just way tougher and more precise for industrial stuff. Timing stays tight, they don’t freak out from noise or heat, and they can flag issues and shut things down instantly if something looks off.

It basically adapts on the fly—tweaks its power, shifts frequencies when things get noisy, and sorts through a pile of tags without choking. Since the antennas take turns hitting the box from different angles, even the hidden or crooked tags still get read.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.