Submit your request to us

We will contact you as soon as possible.

All RFID Product

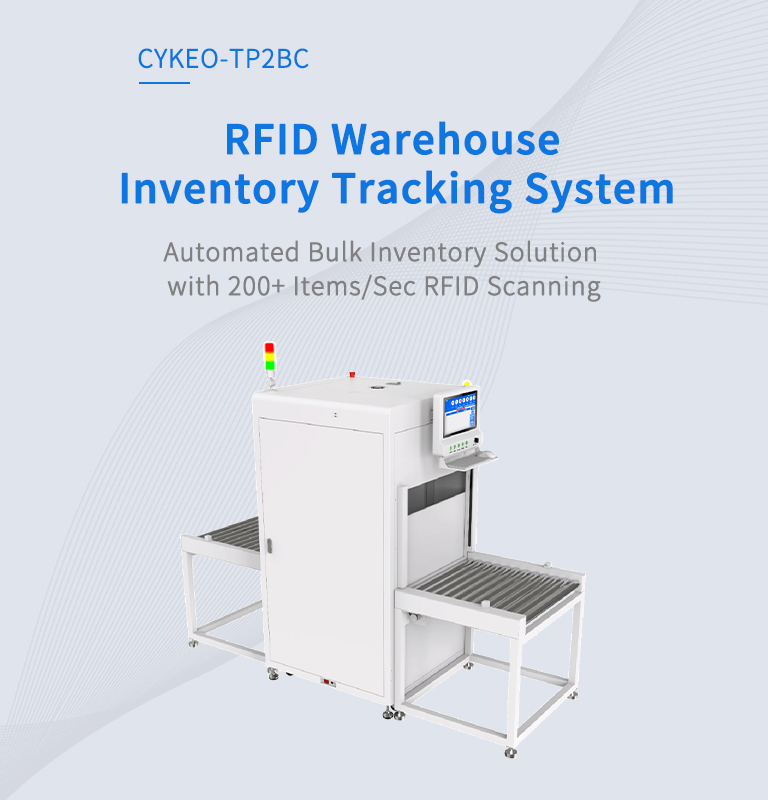

CYKEO-TP2BC

Automated Bulk Inventory Solution with 200+ Items/Sec RFID Scanning

✔️ Industrial Shielding for 99.9% Inventory Accuracy

✔️ 200+ Items/Sec RFID Tracking with Anti-Miss Technology

✔️ Seamless ERP/WMS Integration for Warehouse Workflows

The CYKEO-TP2BC RFID Warehouse Inventory Tracking System is engineered to transform warehouse operations with ISO 18000-6C compliance. This tunnel-based solution scans 200+ items in 3 seconds via a shielded conveyor, eliminating manual errors in apparel, logistics, and high-value goods. The 14-inch touchscreen provides real-time alerts for missing/duplicate items, while Windows/Android OS ensures compatibility with SAP and Oracle systems.

Perfect for rfid warehouse inventory tracking: Bulk garment audits, palletized goods reconciliation, and cold chain container verification.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

The CYKEO-TP2BC RFID Warehouse Inventory Tracking System revolutionizes bulk auditing by combining ISO 18000-6C compliance with industrial automation:

Ideal for: Apparel distributors managing 10,000+ SKUs or 3PL warehouses processing 500+ pallets daily.

The CYKEO-TP2BC tackles complex environments through adaptive RF engineering:

Proven in: Automotive parts warehouses tracking metal components and electronics DCs managing ESD-safe packaging.

Yes—the CYKEO-TP2BC is built for seamless warehouse automation:

Deployment Example: A global beverage company reduced stock discrepancies by 98% by connecting 12 CYKEO-TP2BC units to their Oracle Cloud SCM.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.