Submit your request to us

We will contact you as soon as possible.

All RFID Product

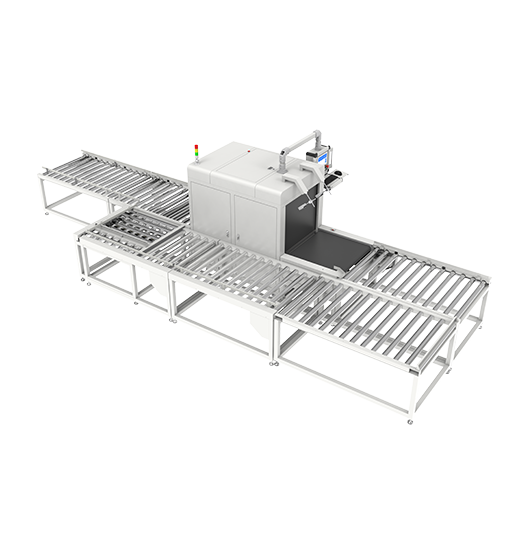

CK-TP2A

Automated High-Volume Verification for Warehouse Logistics

✔️ Scans RFID, barcodes, weighs, and sorts automatically

✔️ 400+ items in just a few seconds

✔️ Auto reject line for anything off

The CK-TP2A speeds up warehouses big time. It scans, weighs, and sorts items in a flash, cuts mistakes, and keeps shipments spot-on.

Perfect for busy spots—cartons in apparel or footwear, e-commerce packs, or any high-volume stock area

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

Four antennas cover all angles, smart anti-collision keeps crowded tags from mixing up, and the shielded conveyor makes sure only the carton inside gets scanned—almost never misses.

It flags it instantly—screen alert, flashing lights—and sends it down the reject line. Every hiccup is logged so managers can see patterns and fix issues fast.

It plugs right in—via API/SDK for real-time updates, or it can drop CSV/XML files your WMS picks up. It also talks to your conveyor PLCs, so scans can automatically start/stop lines or divert cartons. Everything stays synced without slowing things down.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.