Submit your request to us

We will contact you as soon as possible.

All RFID Product

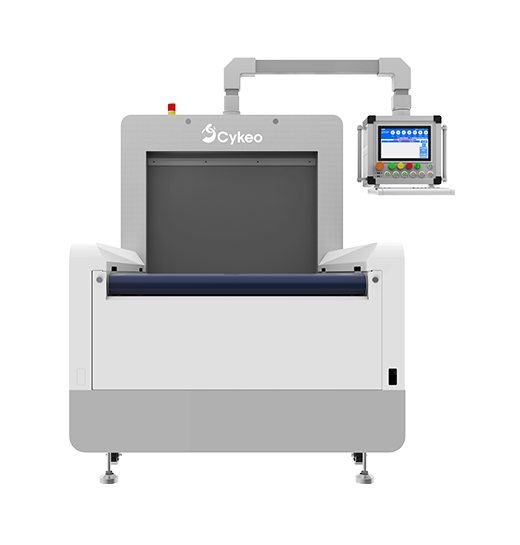

CYKEO-TP2

Automated bulk-scanning setup for busy warehouse and logistics lines

✔️ 400+ items/sec tunnel reads

✔️ ISO 18000-6C, solid anti-collision performance

✔️ Modular conveyor, handles around 80kg without fuss

The CYKEO-TP2 keeps stock checks moving fast—about a 4-meter conveyor paired with 6C readers and full shielding, so tags don’t interfere with each other. The three belts run independently, which helps the system grab clean reads even when boxes are packed tight. In real use, it hits around 99.9% accuracy and handles roughly 6–10 cartons per minute, cutting most of the usual manual counting work.

Great for high-volume RFID jobs in apparel warehouses, liquor distribution hubs, electronics lines—basically anywhere batch verification needs to be quick and reliable.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

It uses a four-antenna phased array setup that basically adjusts its power on the fly, so tags aren’t stepping on each other. The system filters out noise from nearby aisles and focuses only on what’s inside the tunnel. It handles mixed tag types without any drama. In one fashion warehouse, accuracy jumped from double-digit misreads to almost zero after switching to CYKEO-TP2.

Case Study: A European fashion distributor reduced misreads from 12% to 0.3% after deploying CYKEO-TP2 tunnels, handling 8,000 garments/hour across 40 loading docks.

Yeah—this thing plugs into most setups without a fight. It has ready-made connectors for SAP, Oracle, Manhattan and can talk through REST APIs. There’s local storage onboard in case the network drops, and alerts can be customized right from the screen. Even a supplier running an old IBM Maximo system got real-time updates with the CYKEO-TP2 .NET SDK.

It’s built for harsh rooms—freezers, humid plants, the whole deal. The antennas stay warmed so frost doesn’t form, the frame is stainless and sealed, and the sensors can warn you way before a belt wears out. One pharma center ran it in sub-zero temps for over a year with stable reads and no hardware swaps.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.