Submit your request to us

We will contact you as soon as possible.

All RFID Product

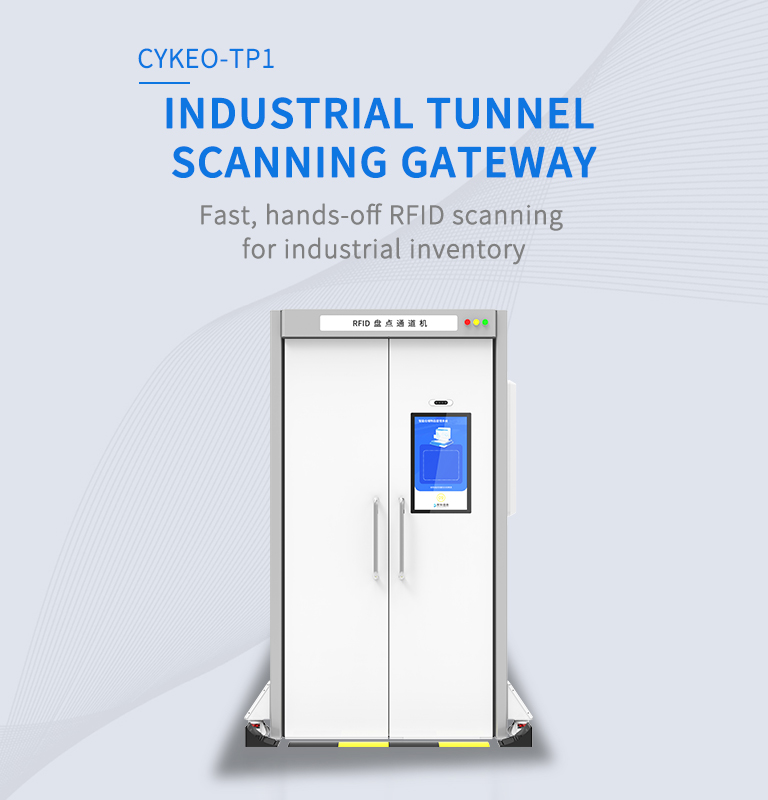

CYKEO-TP1

Fast, hands-off RFID scanning for industrial inventory

✔️ 10cm shielded tunnel to block interference

✔️ 1000+ tags/min bulk scanning

✔️ Tough carbon steel build (IP54)

✔️ Supports ISO18000-6C / EPC C1G2

The CYKEO-TP1 is built for high-density inventory checks. Push carts or pallets through its industrial tunnel, and it reads everything quickly and cleanly. Shielding keeps reads precise, and Windows/Android compatibility makes integration with inventory systems easy.

Perfect for warehouse audits, hotel linen cycles, or apparel distribution centers.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

It uses triple-layer anti-collision logic, 10cm RF shielding, and dynamic power tuning to handle hundreds of tags per second. Dual antennas cover every corner, and duplicate scans get filtered automatically. In real tests, it hit over 99% accuracy even on fully loaded carts with 800+ garments.

Yes. Built tough with IP54 steel housing and temperature-resistant components, it works from -20°C to 60°C. Condensation-proof antennas and anti-corrosion surfaces keep it reading reliably in frozen food warehouses or humid textile facilities.

Minimal. Antenna panels swap in minutes, guide rails clean themselves, and firmware updates are automated. Monthly RF checks, quarterly shielding inspections, and bi-annual power diagnostics keep everything smooth, while the predictive dashboard alerts you before issues pop up.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.