Submit your request to us

We will contact you as soon as possible.

All RFID Product

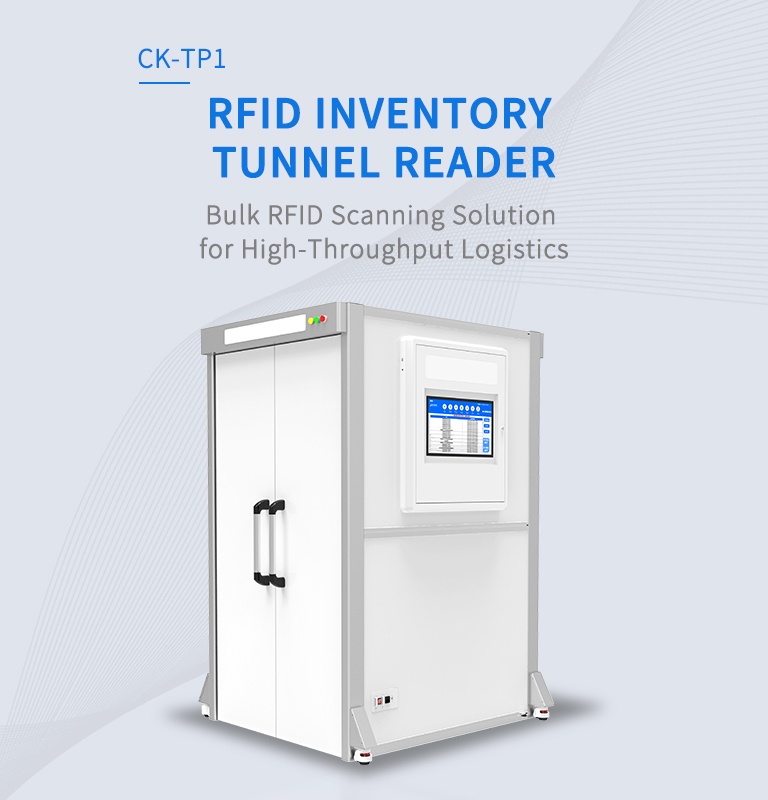

CK-TP1

RFID Inventory Tunnel Reader – High-Speed Bulk Scanning Solution

Enterprise-Grade RFID Tunnel System for Automated Inventory Management

✔️ 1000+ Tags/Min Bulk Inventory Scanning

✔️ ERP/WMS Integration via API/WebSocket

✔️ IP65-Rated Tunnel Design for Continuous Operation

BULK SPEED, ZERO MISS

The CK-TP1 RFID Inventory Tunnel Reader revolutionizes warehouse operations with its 1220×2205mm scanning portal, achieving 100pcs/sec bulk RFID detection for apparel, electronics, and logistics containers. Featuring dual anti-collision doors and 10cm signal shielding, it ensures 99.9% accuracy in high-density inventory environments.

Cross-industry bulk inventory verification: Ideal for apparel warehouse cycle counts, power meter batch inspections, and logistics container RFID verification processes.

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

The CK-TP1 RFID Inventory Tunnel Reader combines multi-antenna spatial diversity and real-time validation algorithms to achieve unmatched accuracy:

Engineered for challenging industrial applications, the CK-TP1 excels in metal-dense environments through adaptive frequency management and shielding technology:

The CK-TP1 enables enterprise-scale integration through flexible connectivity and data protocols:

Implementation: A global 3PL provider reduced cycle count labor costs by 62% after deploying 35 CK-TP1 tunnels across 12 countries.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.