Submit your request to us

We will contact you as soon as possible.

All RFID Product

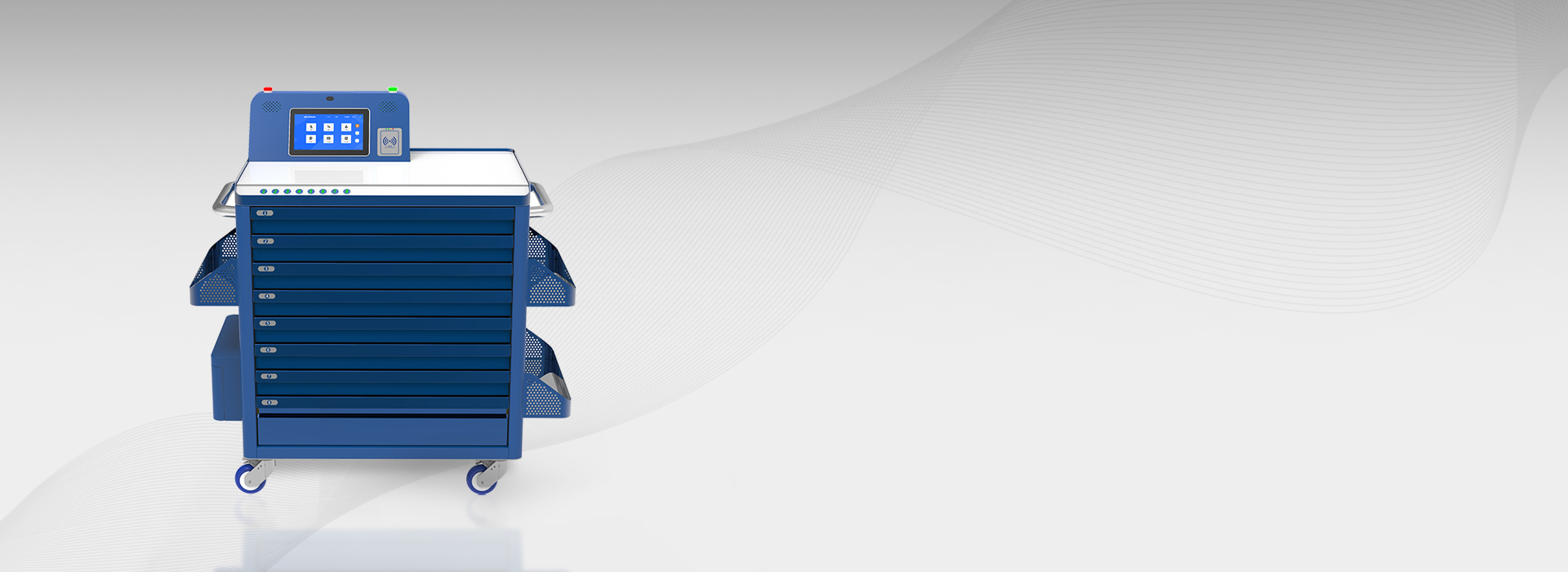

CK-TC

UHF RFID Tool Control, Built for Real Work

✔️ IP54-rated, handles real factory floors without drama

✔️ Biometric access, instant alerts when something’s off

✔️ Holds ~300 tools, tracked drawer by drawer

The CK-TC is basically a tool cart that actually knows what’s inside it. Roll it where you need it, tap the 10.1″ screen, and it scans hundreds of RFID-tagged tools in seconds. No counting. No guessing. Powered by an Impinj R2000, running Windows or Android, and it plugs straight into systems like SAP without a fight.

It’s built for places where mistakes aren’t an option. Fire stations keep rescue gear accounted for on the truck. Nuclear sites know exactly where every specialized tool is. Rail depots run inspections without chasing missing equipment.

Not flashy. Just solid control, clear records, and fewer headaches.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

In short, the cart knows which drawer a tool belongs to. Every drawer reads its own tags, so even tiny stuff like screws or drill bits doesn’t get mixed up. Put something back in the wrong place and the screen calls it out immediately. In real workshops, that alone cuts losses hard—people notice fast, fix it on the spot, and move on instead of “I’ll find it later.”

Yes. When the power drops, the cart doesn’t go blind. With solar and built-in battery backup, it keeps access control and logging alive, even in cold weather. You may lose full scanning during deep outage mode, but doors, alarms, and user records keep running. For remote sites, that’s usually what matters most—nothing goes missing while nobody’s watching.

Honestly, it removes the paperwork pain. Every tool has a name on it—who took it, when, and when it was supposed to come back. Reports are generated automatically, not stitched together the night before an audit. Companies using it usually find audits faster, quieter, and way less stressful, because the data’s already there and nobody has to “explain” missing tools anymore.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.