Submit your request to us

We will contact you as soon as possible.

All RFID Product

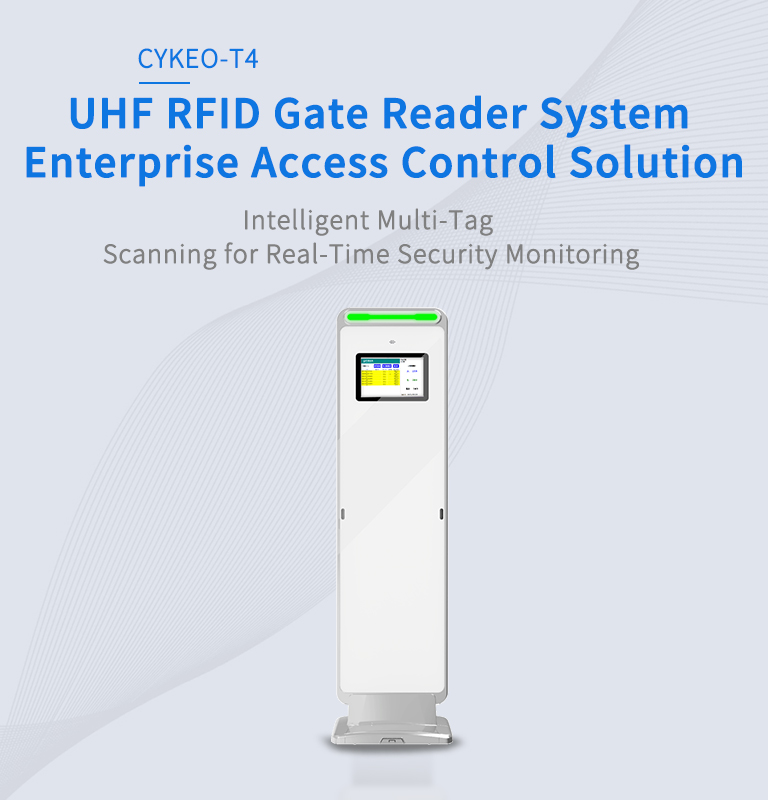

CYKEO-T4

Intelligent Multi-Tag Scanning for Real-Time Security Monitoring

✔️ Scans 300+ tags/sec with 99.9% accuracy

✔️ Infrared trigger and dual EAS alarms

✔️ Rugged IP54 aluminum frame

✔️ Connects via WiFi, 4G, or RS232

The CYKEO-T4 reads multiple tags quickly (0–6 m), triggers scans via infrared, and sounds EAS alarms. Built tough (-10°C to 60°C) with WiFi, 4G, or Ethernet, it fits libraries, retail, warehouses, or events for smooth, secure tracking.

Main Specifications

Physical Parameters

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

Developer Support

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

0–6 m, best at 1.2 m. Adjust power, use all antennas, avoid metal, and let infrared trigger scans.

Reads 200+ tags/sec, filters by signal, and scans only when someone moves—accurate even in busy spots.

It works with Ethernet or RS232, and add WiFi or 4G—fits old setups, cloud, or remote monitoring.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.