Submit your request to us

We will contact you as soon as possible.

All RFID Product

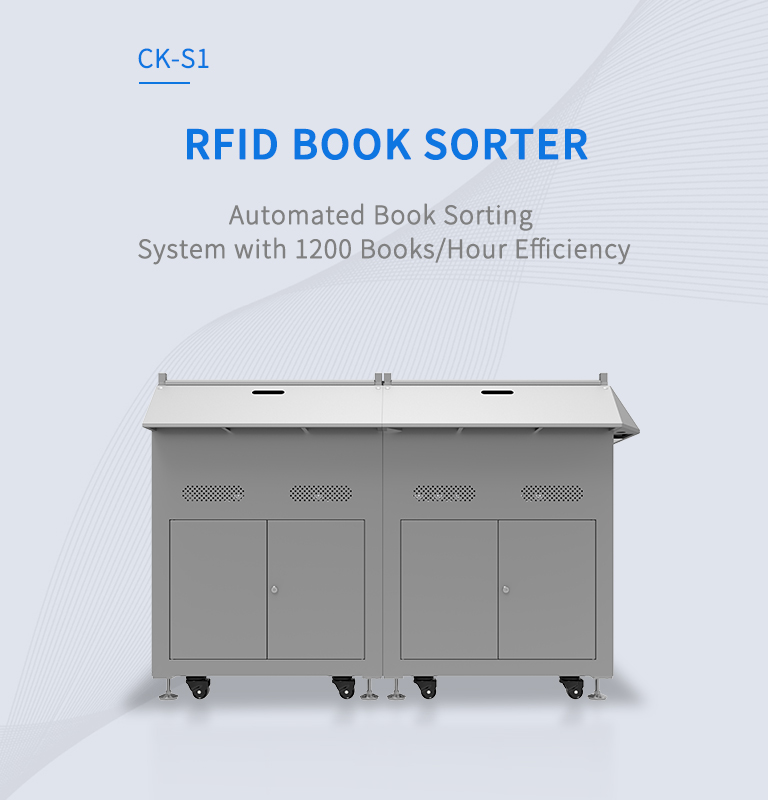

CK-S1

High-speed RFID book sorter that handles around 1200 books per hour.

✔️ 1200 books/hour sorting

✔️ 1-inlet, 3-outlet modular setup

✔️ Works with 24/7 return systems

The CK-S1 is a fast, flexible RFID sorting system that takes returned books and drops them into the right bins automatically. It supports both HF and UHF tags, runs over 1200 books an hour, and the modular design lets you expand the outlets when you need more capacity. It keeps sorting accurate and cuts a lot of manual handling, especially for libraries running all day and night.

Great for public libraries, university libraries, and book distribution centers that want quick, reliable sorting without extra labor.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

You start with a 1-in/3-out setup, and when you need more lanes, you just bolt on extra modules. Each one adds two more outlets, and the main controller picks them up automatically—no tricky configs.

Pretty much anything libraries throw in—small paperbacks, big heavy books, magazines, DVDs, odd-shaped stuff, even softer books. The system adjusts to size and weight and handles everything gently.

The RFID readers catch tags from different angles, the timing is super tight, and the sensors keep an eye on everything. If a book goes weird, the system fixes it or flags it right away.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.