Submit your request to us

We will contact you as soon as possible.

All RFID Product

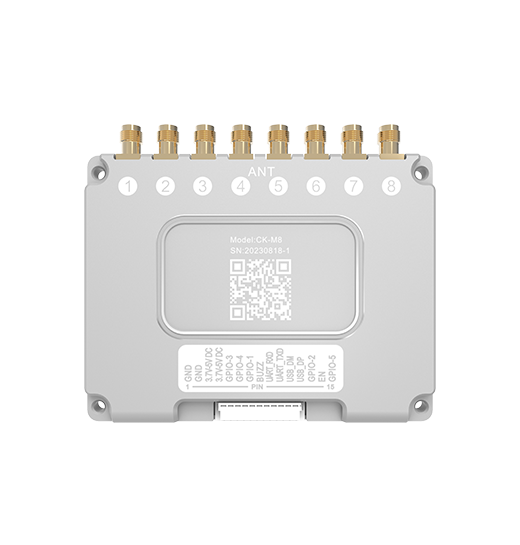

CYKEO-M8

8-channel UHF RFID module built for real multi-antenna work

✔️ 33 dBm output, adjustable in fine 1 dB steps

✔️ R2000-based RF design for stable, repeatable reads

✔️ ISO 18000-6C / EPC C1G2 and GB standards supported

✔️ 600+ tags per second when labels are stacked or moving

The CYKEO CYKEO-M8 Module RFID is made for setups where one antenna simply isn’t enough. With eight independent RF channels and an Impinj R2000 core, it’s designed to read many tags at the same time without collapsing under load.

Power output stays consistent across all ports, covering 940–960 MHz. The module supports fixed frequency or hopping modes, depending on how noisy the environment is. In automated warehouses and production lines, CYKEO-M8 is commonly mounted inside control cabinets, AGVs, or conveyor systems where antennas need to cover multiple zones at once.

There’s no complicated tuning to get started. Supply 5 V power, connect via TTL, call the API, and it starts working. Dense-reader algorithms and tag filtering are handled on the module itself, which keeps upstream systems clean and responsive.

Typical applications include pallet tracking, robotic sorting, work-in-process control, and smart factory stations where accuracy matters more than raw distance.

Main Specifications

Physical Parameters

Developer Support

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

Spacing and control matter more than brute force.

Use multiple antennas to divide read zones, enable dense reader mode, and set RSSI limits so only relevant tags are captured. On moving conveyors, CYKEO-M8 consistently clears tightly packed pallets in seconds, even when tags overlap.

That’s why it’s often used on AGVs and automated warehouse lanes where missed reads cause real delays.

Yes—if you treat metal properly.

CYKEO-M8 relies on frequency hopping, RF shielding, and precise power control to reduce EMI from welding robots and presses. Pair it with on-metal UHF tags, leave a small air gap where possible, and narrow the read field to the work area.

In paint shops and assembly cells, read rates stay above 95% even with heavy machinery nearby.

Surprisingly, yes.

The module supports deep sleep, scheduled scans, and event-based triggers. It processes and filters tag data locally, which cuts down unnecessary data transmission and power draw.

In cold-chain storage and agricultural sites, CYKEO-M8 systems have run for days on solar setups without sacrificing read stability—even in low temperatures.

CYKEO Module RFID solutions are widely used in automated warehouses, smart manufacturing lines, industrial IoT gateways, and multi-antenna tracking systems. Designed for long-term deployment where stability, protocol compatibility, and dense tag performance are critical.