Submit your request to us

We will contact you as soon as possible.

All RFID Product

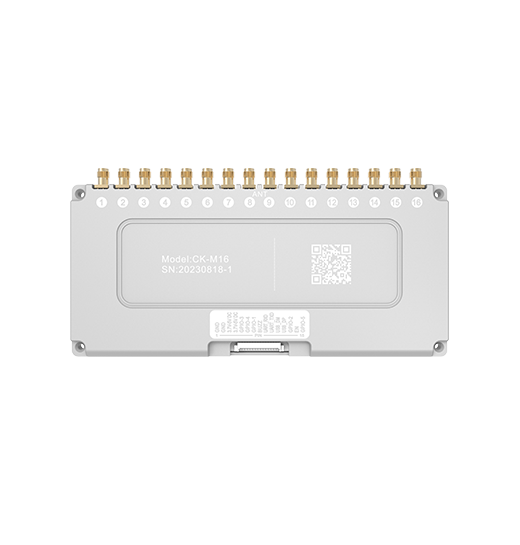

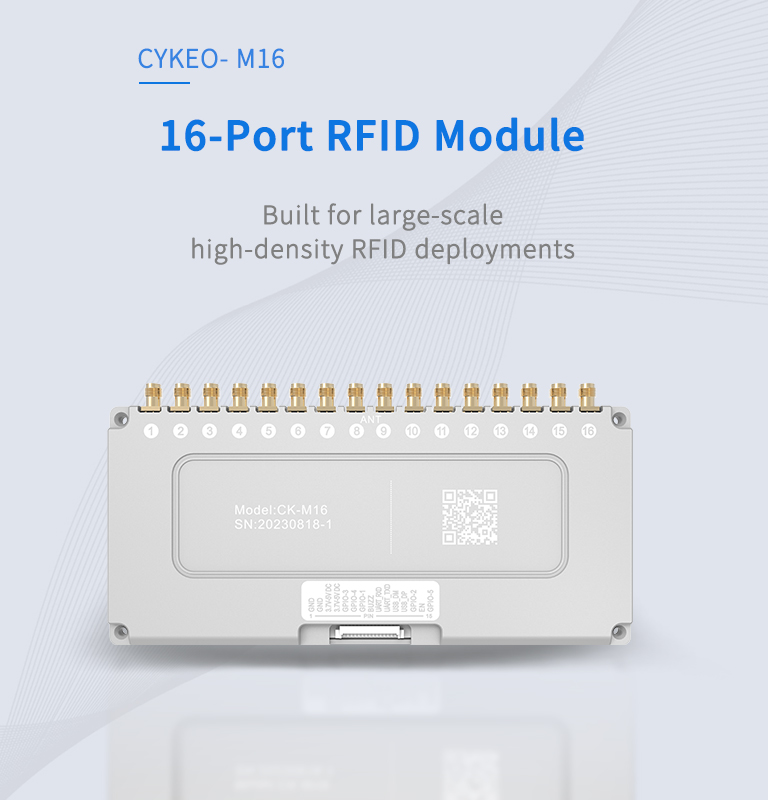

CYKEO-M16

Built for large-scale, high-density RFID deployments

✔️ Handles 600+ tags per second using the R2000 platform

✔️ Compatible with ISO and GB RFID standards

✔️ Full control of up to 16 antenna ports

The CYKEO CYKEO-M16 RFID Module is designed for projects where tag density and antenna count quickly get out of hand. Built around the Impinj R2000, it keeps read performance stable even when dozens of labels sit in the same space.

Each RF port delivers up to 33 dBm with 1 dB step adjustment, which makes it easier to shape read zones instead of flooding everything with power. Fixed-frequency and hopping modes are both available, depending on how noisy the site is.

Integration is straightforward. Power it at 5 V, connect over TTL/UART, and control everything through the API. Most deployments don’t need extra RF tuning—the module is already optimized for dense environments.

Typical use cases include multi-station assembly tracking, smart lockers with shared antenna grids, large logistics sorters, tool cabinets, and energy facilities where long antenna runs and overlapping zones are unavoidable.

Main Specifications

Physical Parameters

Developer Support

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

It’s less about raw power and more about layout.

Split coverage across antennas, enable dense reader mode, and apply tag filters early. With proper antenna angles and RSSI thresholds, CYKEO-M16 clears packed pallets in seconds, even when conveyors don’t slow down. That’s why it’s often chosen for AGVs and automated sorting lines.

Yes, but placement still matters.

The module uses frequency hopping, shielding, and precise power control to stay readable near welders and fixtures. Pair it with on-metal tags, keep a small air gap when possible, and limit read zones to the task area. Even in paint shops and high-EMI zones, read rates remain consistent.

Surprisingly well.

CYKEO-M16 supports deep sleep, scheduled scans, and event-based triggers. Tag filtering happens locally, so only useful data goes upstream. In cold-chain warehouses and agricultural sites, systems have stayed online for days on solar power without losing read accuracy—even below freezing.

CYKEO RFID Module solutions are deployed across logistics, smart manufacturing, healthcare asset tracking, aviation maintenance, energy infrastructure, and industrial IoT systems. They are built for long-term operation where dense tags, multiple antennas, and stable performance matter more than lab conditions.