Submit your request to us

We will contact you as soon as possible.

All RFID Product

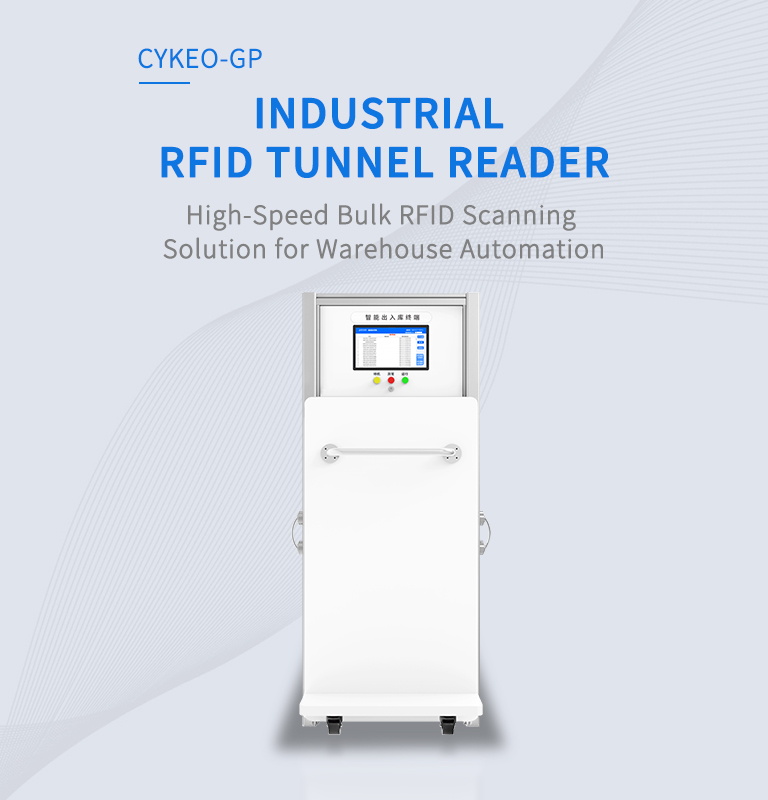

CYKEO-GP

High-Speed Bulk RFID Scanning Solution for Warehouse Automation

✔️ 300 tags/sec inventory tracking

✔️ ISO 18000-6C/EPC C1G2 & bulk data export

✔️ 20 cm anti-interference shielding

The CYKEO-GP speeds up RFID inventory with a 1.9 m tunnel for warehouse carts. Scans 300+ tags/sec for meters, textiles, or retail goods. Perfect for pallet checks, hotel linen audits, and real-time tracking in busy distribution centers—fast, precise, zero missing.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

Four antennas scan overlapping zones, auto-adjust power, and filter duplicates. Batch prioritization and on-screen verification cut missed reads—99.8% accuracy at 300+ tags/sec.

Yes. APIs for SAP, Oracle, Zebra, plus CSV/XML/JSON export. Java/C# SDK lets you trigger scans and map tags to your inventory. One client cut reconciliation time 70% on 10,000+ assets.

Absolutely. Works -20°C to 60°C with heated components, stable antennas, and voltage stabilizer. Touchscreen is sun-readable, glove-friendly, and battery backup keeps scans going 30+ min.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.