Submit your request to us

We will contact you as soon as possible.

All RFID Product

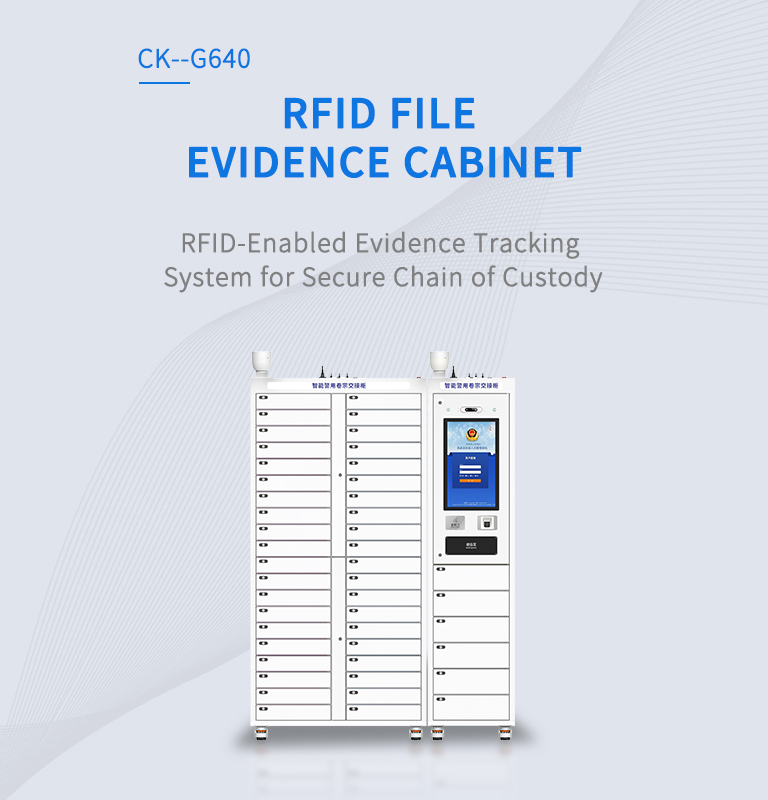

CK-G640

Smart Evidence Tracking for Secure Custody

✔️ 1-Second RFID Scan

✔️ Up to 40 Compartments

✔️ 24/7 Unattended Operation

✔️ 500 Files, Full Scan in <5s

The CK-G640 tracks evidence with 99.98% accuracy, using RFID to keep everything organized. Expand from 6 to 40 compartments, sync it with cloud platforms, and let the system handle everything. Perfect for law enforcement and legal spaces that need secure, automated evidence management.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

Local Data: Even without power, all data stays saved locally. Once the power’s back, it syncs to the cloud.

Battery Backup: A UPS kicks in and keeps things running for hours, so no worries.

Manual Access: If the system’s down, you can still open it manually. All actions are logged.

Focused Scan Zone: It scans one item at a time, no interference.

Sequential Reading: The system reads tags in order, avoiding overlap.

Power Control: Adjusts signal strength to keep everything clear and precise.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.