Submit your request to us

We will contact you as soon as possible.

All RFID Product

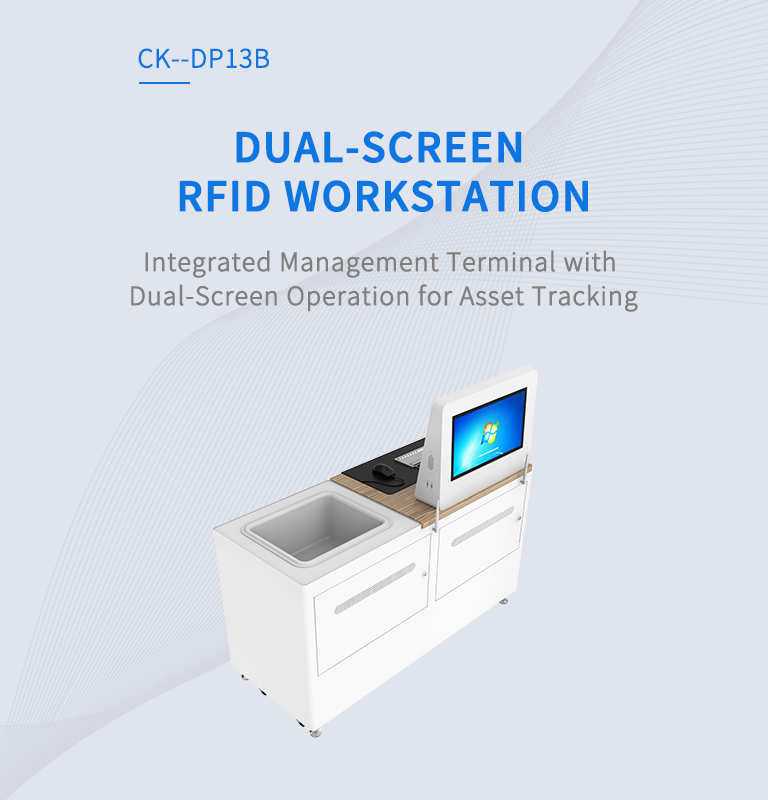

CK-DP13B

All-in-one station for fast, secure asset tracking.

✔️ Dual 21.5″ touchscreens

✔️ Scan 100 RFID tags at once

✔️ Built-in camera & access control

RFID Workstation System for Asset Tracking

he CK-DP13B is a dual-screen workstation that makes asset tracking simple. Scan up to 100 items at once, capture high-res documents, and control who can access what—all from one system. Optional weighing adds extra tracking. Perfect for tool rooms, inventory centers, and any place where managing assets securely and efficiently matters.

The CYKEO CYKEO-D4L UHF RFID Tag Reader is a stable Desktop RFID Reader designed for accurate tag registration, borrowing, and return workflows. Built with the Impinj R2000 chip, this UHF RFID Tag Reader delivers controlled short-range reads for l…

Cykeo’s CYKEO-D8C UHF RFID gate reader achieves 200-tag/batch scanning with adjustable power control, ideal for retail inventory and smart warehouse management.

CYKEO CYKEO-D1C USB RFID Card Reader is a near-field UHF desktop writer designed for secure, short-range tag encoding. With USB-C connectivity and stable 26 dBm output, this rfid reader usb c is ideal for badge issuance, label encoding, and contro…

Cykeo CYKEO-D8A embedded RFID badge reader offers 30+ tags/sec scanning, 20cm anti-crosstalk precision, and DC 12V power for unmanned stores, warehouses, and smart inventory systems.

The CYKEO CYKEO-D6L RFID Reader Writer is a heavy-duty Desktop RFID Reader designed for short-range, high-accuracy tag programming. Built for libraries, labs, and asset desks, this RFID Reader Writer supports batch processing, stable 33dBm output,…

loading…

已经是到最后一篇内容了!

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

With two screens, you can do two things at once. One shows the registration form, the other shows real-time RFID results. No more switching windows—errors get caught instantly. It’s also great for training or showing info to customers while you manage the backend. Basically, you stay focused on the main task while having all supporting info visible.

The recessed well keeps items in the sweet spot for scanning, so placement errors are reduced. It blocks outside interference from metal or other electronics, making reads more reliable. Plus, it guides operators visually and tactilely, so first-pass scans succeed more often.

The integrated camera captures high-res images of assets at check-in/out, so you have a visual record of condition. It can also digitize documents like invoices or warranties and link them to the asset. On top of that, it can capture user photos for authentication, giving a solid, traceable audit trail.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.