Submit your request to us

We will contact you as soon as possible.

All RFID Product

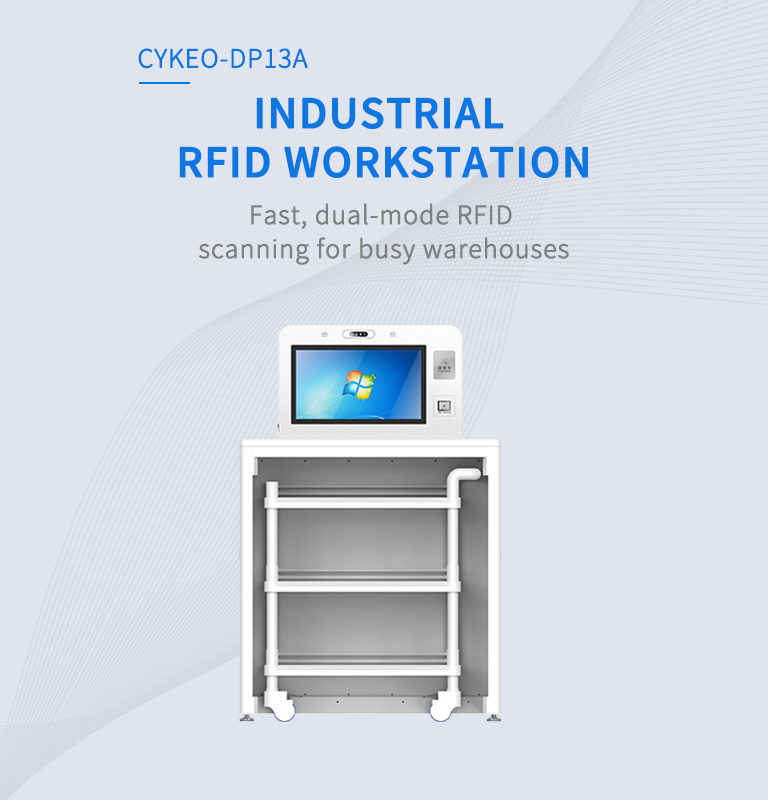

CYKEO-DP13A

Fast, dual-mode RFID scanning for busy warehouses

✔️ Tunnel reads 200+ items/sec

✔️ Barcode, ID, and facial recognition built-in

✔️ Windows/Android with multi-user login

The CYKEO-DP13A handles quick checks and bulk scans without slowing down. Desktop mode zips through 50+ items in seconds, the tunnel blasts 200+ with near-perfect accuracy. Tough steel build and multi-level security keep things running smooth.

Perfect for pharma batches, auto parts, or fast-paced retail warehouses.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

The CYKEO-DP13A makes it simple. You can set scanning rules per zone—high-value areas get precise reads, bulk zones scan faster. AI maps the best route to cut walking time, and all zone data syncs automatically to your ERP every couple of minutes. Big warehouses have cut cycle counts from days to hours and still hit near-perfect accuracy.

It reads hundreds of tags at once, even through boxes or stacked pallets. The system boosts weak signals, ignores duplicate tags, and flags mismatches in real time. For busy warehouses or retail, this dramatically reduces shipping or stock errors compared to scanning one barcode at a time.

It runs self-checks daily, clears memory automatically, and updates firmware over the air. Modules and filters are easy to swap without tools, and preventive kits help calibrate antennas or clean touchscreens. Even in freezing warehouses, heated antennas keep reads consistent, so uptime stays at 100%.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.