Submit your request to us

We will contact you as soon as possible.

All RFID Product

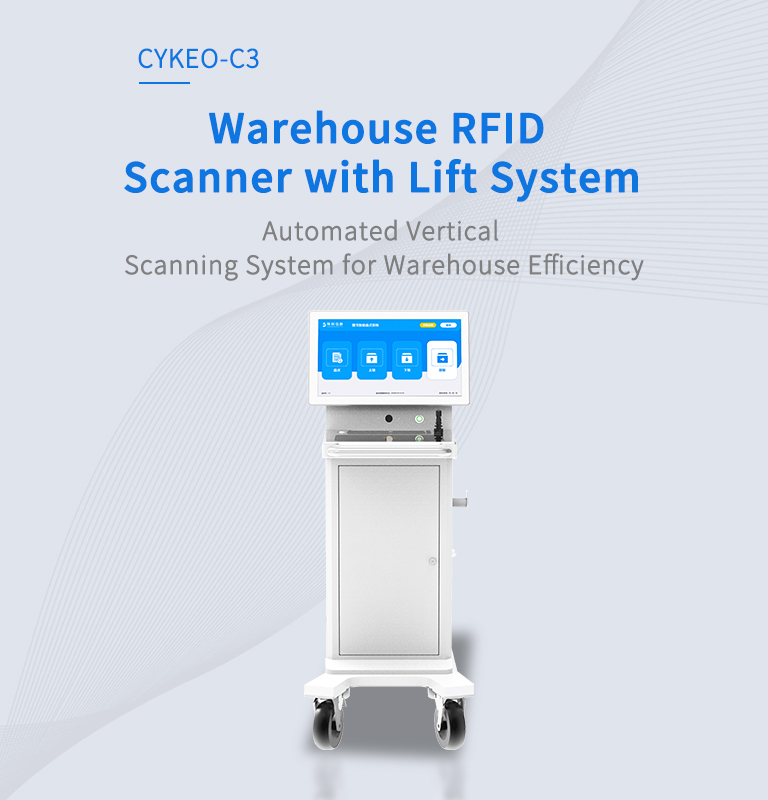

CYKEO-C3

Automated Vertical Scanning System for Warehouse Efficiency

✔️ Lift goes up to about 2.2m, so high shelves aren’t a pain

✔️ Dual antennas pull in 800+ tags a minute

✔️ Runs offline on a Windows touchscreen—simple and dependable

ELEVATE EFFICIENCY, SCAN SMARTER

The CYKEO-C3 basically takes the climbing and guesswork out of stock checks. The lift moves smoothly and stops right where you need it, and the antennas cover the whole scan lane in one pass. The built-in Windows screen keeps everything easy to manage, and it keeps working even if the network decides to go down. It’s the kind of tool that saves time on tall racks, quick counts, and keeping storage rows organized without a lot of fuss.

Works great for day-to-day warehouse tasks—fast bulk scans, grabbing tags from higher shelves, and cleaning up inventory layouts in manufacturing or logistics spaces.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

It basically takes the climbing and back-and-forth out of the job. The lift reaches a little over 2 meters and stays steady, so you can scan high shelves without ladders. The two antennas pick up tags fast—even in crowded racks—and you can save different height presets so you’re not scanning the same spots twice. Warehouses running tall shelves have seen big jumps in accuracy and way less time spent on cycle counts.

Yep. It switches between UHF and HF right from the touchscreen, so you can scan pallet goods, electronics, tools—whatever’s tagged. The system avoids frequency clashes, and if you need to double-check small HF items, the built-in desktop reader gets super close and precise. Places handling both big components and tiny electronics cut misreads by a huge margin after switching to this setup.

The enclosure is sealed well enough to keep dust out, and the electronics are built to resist moisture and condensation. The lift and motor are shock-proof, so bumps from forklifts or nearby machines don’t throw it off. Stay on top of simple cleaning and occasional recalibration, and it just keeps running—even in tough environments like mills, cold rooms, or humid warehouses.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.