Submit your request to us

We will contact you as soon as possible.

All RFID Product

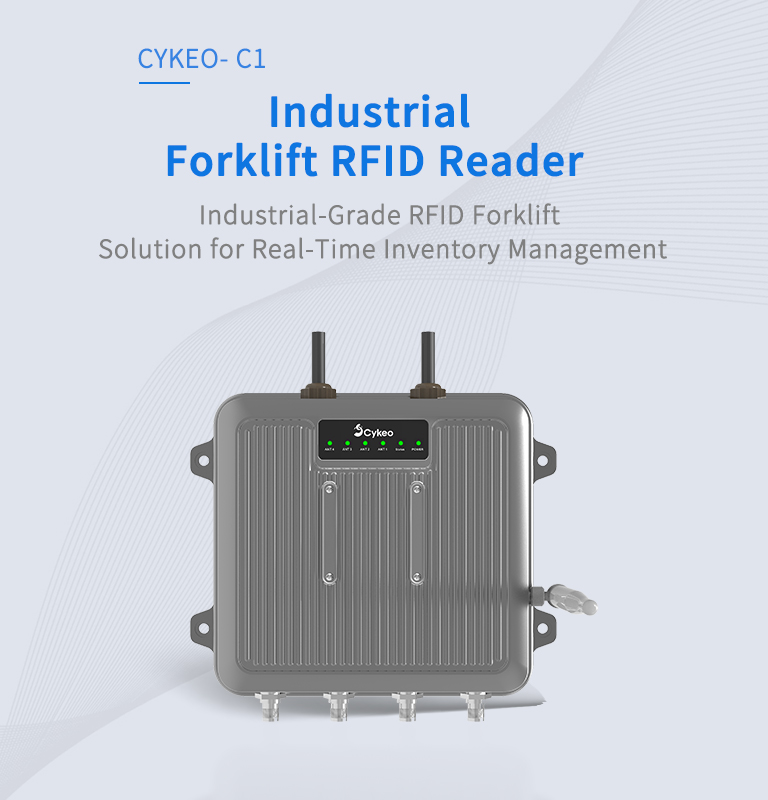

CYKEO-C1

Industrial-Grade RFID Forklift Solution for Real-Time Inventory Management

✔️ Seamless Integration with WMS and ERP Systems

✔️ Rugged IP67 Design for Vibration-Prone Environments

✔️ 600+ Tags/Sec Multi-Port Reading with UHF Technology

CYKEO-C1 Industrial Forklift RFID Reader is built tough for mobile use. With four antenna ports and the Impinj R2000 chipset, it can read over 600 tags per second, even in busy, rough conditions. It’s vibration-resistant and fully waterproof (IP67), so it keeps running reliably on forklifts in warehouses or on production floors. It tracks pallets in real time and connects easily to most logistics management systems.

Whether it’s keeping tabs on warehouse stock, feeding a production line, or managing a hectic yard, the CYKEO-C1 gets the job done without fuss.

Main Specifications

Physical Parameters

Developer Support

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

CYKEO-C1 really shines in a busy warehouse. It can read over 600 tags every second, and the four TNC antennas mean you basically get full coverage even when forklifts are moving around. On top of that, it’s smart enough to skip duplicate reads on stacked pallets, so you’re not drowning in repeated data.

CYKEO-C1 can take bumps and shakes without missing a beat, thanks to its anti-vibration design. It quietly adjusts its power in small steps to keep up with changing conditions, and it’s always watching signal strength so tags get read correctly—even when everything around it is moving.

CYKEO-C1 keeps running from -20°C up to 60°C, so it doesn’t mind freezer warehouses or blazing sun outside. Its IP67-rated housing handles dust, splashes, and rainy shifts without complaining. Plus, it meets MIL-STD-810G, so a little vibration from forklifts or industrial vehicles won’t faze it.

CYKEO-C1 helps prevent SKU mix-ups by tightening read zones around the forks and filtering tag groups by EPC prefix. When pallets contain mixed items or when similar cartons sit close together, the reader uses antenna phasing to keep reads limited to the pallet being moved. This reduces stray tag captures and gives WMS systems cleaner data, which is especially useful in fast-moving DCs or factories with frequent SKU changes.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.