Submit your request to us

We will contact you as soon as possible.

All RFID Product

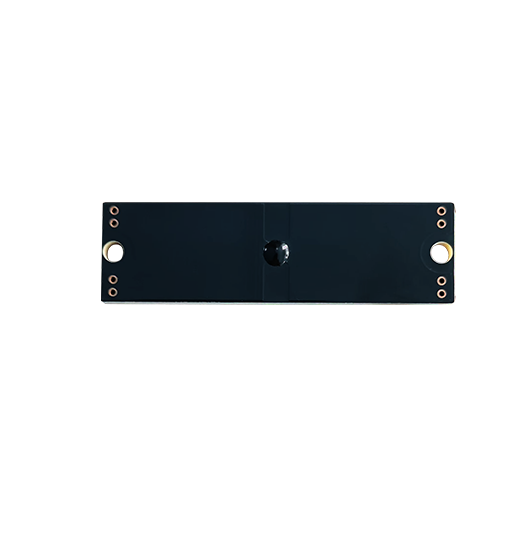

CK-BQ7020

RFID anti-metal tags are designed specifically for tracking physical metal assets.

✔️ Over 5 meters read range directly on metal

✔️ IP68 sealed, resists chemicals and fluids

✔️ 100k+ rewrites with up to 20 years data life

The CK-BQ7020 is an on-metal RFID tag built for places where metal is unavoidable and conditions are rarely friendly.

Its FR4 and epoxy resin body gives the tag mechanical strength and electrical stability, while the internal chip options from NXP and Impinj keep performance consistent across UHF systems. Once mounted on steel, racks, poles, or equipment housings, the tag stays readable instead of being swallowed by interference.

This RFID anti-metal tag works reliably from -40 °C to +85 °C and tolerates storage temperatures even higher. It resists oil, alcohol, fuel splashes, and daily industrial wear. That makes it a solid choice for heavy equipment tracking, outdoor infrastructure, warehouse racking, and medical or automotive assets where metal is part of the job.

Main Specifications

Physical Parameters

Developer Support

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

By using the right structure instead of brute power.

The FR4 epoxy housing protects the electronics and gives IP68 sealing against dust, water, and chemicals. A controlled spacing between the antenna and metal surface helps maintain signal stability. Even after vibration, drops, UV exposure, oil contact, and temperature swings, field tests show consistent read performance over long periods.

It depends on how permanent the asset is.

For high-vibration equipment, stainless screws lock the RFID anti-metal tag in place. For smooth metal surfaces, 3M industrial adhesive works well. Epoxy bonding is best for rough or curved metal that won’t be moved again. In outdoor tests, properly installed tags stay readable for years with no special maintenance.

Metal-heavy spaces are noisy for RF.

The CK-BQ7020 uses a directional antenna layout and stable UHF tuning to reduce reflections. In dense environments like warehouses or factories, it maintains clean reads and works smoothly with industrial on-metal RFID tag applications, even when many assets sit close together.

CYKEO designs RFID hardware for environments where materials, temperature, and handling conditions are unpredictable. From rugged On-Metal RFID Tags and RFID anti-metal tag solutions to complete UHF tracking systems, CYKEO supports logistics operations, industrial manufacturing, healthcare asset control, energy infrastructure, transportation facilities, and long-term outdoor asset management.