Submit your request to us

We will contact you as soon as possible.

All RFID Product

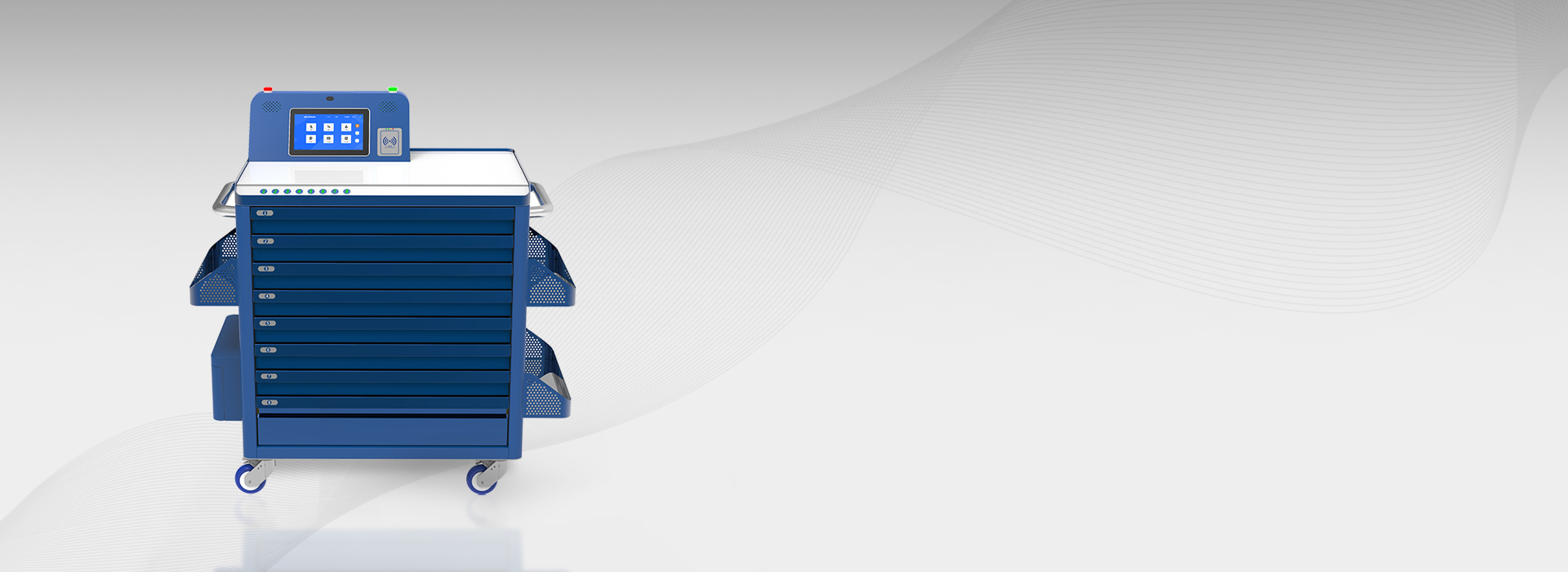

CA-TC

RFID Multi-Drawer Tool Cart

Automated UHF RFID Cabinet for Zero-Error Industrial Tool Control

✔️ Industrial-Grade IP54 for Factory Floors

✔️ Biometric Access Control & Real-Time Alerts

✔️ 300-Tool Capacity with Multi-Drawer RFID Tracking

SCAN ON WHEELS, CONTROL AT FINGERTIPS

The CK-TC RFID Multi-Drawer Tool Cart redefines industrial asset management with UHF RFID technology. Engineered for nuclear plants and railway depots, its Impinj R2000 chip scans 300+ tagged tools in 8 seconds via 10.1″ touchscreen. With Windows/Android OS and SAP integration, it enables tamper-proof logging, humidity control, and solar-powered operation for 24/7 reliability.

Perfect for critical tool management: Fire stations track rescue gear in emergency vehicles, nuclear facilities audit radiation-proof equipment, and rail depots maintain 99.9% inventory accuracy for safety inspections.

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

The CK-TC solves small-tool tracking challenges through 3-tier precision technology:

① Per-Drawer Antenna Arrays: Each of the 6 drawers has 4 dedicated UHF antennas (Impinj R2000) scanning tools as small as M3 bolts, with ±2cm positional accuracy via RSSI triangulation.

② Size-Adaptive Filtering: Algorithms ignore non-tool RFID signals (e.g., worker ID cards) by setting EPC length thresholds (e.g., filter tags <96-bit).

③ Real-Time Zone Alerts: If a drill bit is returned to a wrench drawer, the 10.1″ touchscreen flashes the drawer location and sounds a 90dB alarm.

Case Study:

At Siemens Rail Automation Factory (Germany), CK-TC reduced M4 screw losses by 92% in assembly lines. Previously, monthly losses averaged 1,200 pieces; post-deployment, losses dropped to 96 pieces/month with 99.6% scan accuracy.

Best Practices:

Yes. The CK-TC’s hybrid power architecture ensures uninterrupted operation:

① Primary Power: Standard AC110-220V with lightning/surge protection.

② Backup System:

Performance Metrics:

| Scenario | Duration | Functionality Maintained |

|---|---|---|

| Full Power | ∞ | All features |

| Solar Backup | 48 hrs | RFID scan + access log |

| Emergency Mode | 72 hrs | Alarm + biometric auth |

The CK-TC automates compliance via 4 digital governance features:

① Biometric Chain of Custody: Every tool removal requires fingerprint/face scan, recording:

ROI Example:

Petrobras (Brazil) achieved ISO 55001 certification 5 months faster using CK-TC. Audit preparation time dropped from 200 man-hours/month to 15 man-hours/month, while tool misuse incidents decreased by 78%.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.