Submit your request to us

We will contact you as soon as possible.

All RFID Product

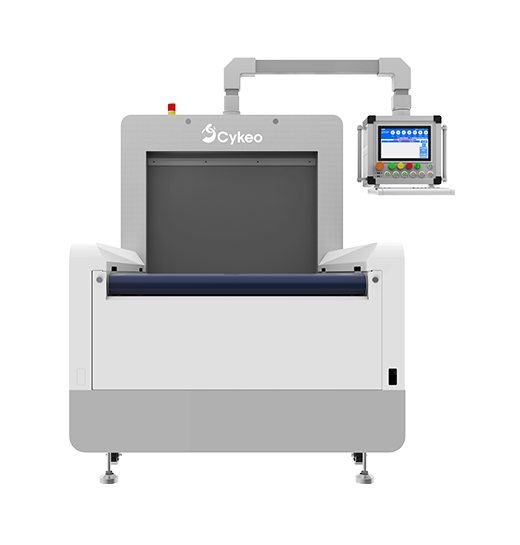

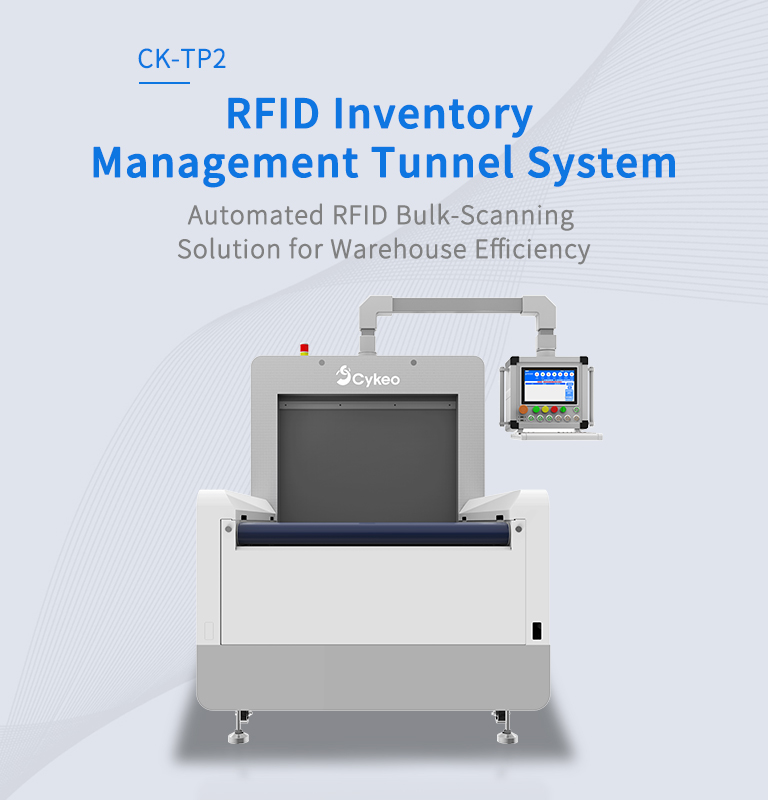

CK-TP2

RFID Inventory Management Tunnel System

Automated Bulk Scanning Solution for Warehouse & Logistics

✔️ 400+ Items/Sec Tunnel Scanning

✔️ ISO 18000-6C Anti-Collision Protocol

✔️ Modular Conveyor Design with 80kg Payload

PRECISION IN MOTION

The CK-TP2 RFID Inventory Management Tunnel System revolutionizes stocktaking operations with its 3965mm conveyor belt integrated with ISO 18000-6C compliant readers. Featuring electromagnetic shielding and triple independently-controlled belts, this industrial-grade solution achieves 99.9% scanning accuracy while processing 6-10 boxes per minute, reducing manual inventory costs by 90%.

Essential for high-volume RFID inventory management in apparel warehouses, liquor distribution centers, and electronics manufacturing facilities requiring batch verification.

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

The CK-TP2 RFID Inventory Management Tunnel System employs quad-antenna phased array technology to overcome challenges in densely packed warehouses:

Case Study: A European fashion distributor reduced misreads from 12% to 0.3% after deploying CK-TP2 tunnels, handling 8,000 garments/hour across 40 loading docks.

The CK-TP2 is engineered for seamless interoperability with existing infrastructure:

Inventory_ID → WMS Stock Keeping Unit (SKU)Location_Stamp → Warehouse Zone/Bin CoordinatesTimestamp → Last Scanned DateIntegration Example: An automotive parts supplier integrated CK-TP2 with their 20-year-old IBM Maximo WMS using the provided .NET SDK, achieving real-time updates for 50,000+ SKUs without system downtime.

esigned for harsh environments, the CK-TP2 RFID Inventory Management Tunnel System delivers unmatched reliability:

Durability Test: In a -18°C pharmaceutical distribution center, CK-TP2 tunnels maintained 99.5% read accuracy over 18 months, processing 12M vaccine vials with zero hardware replacements.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.