Submit your request to us

We will contact you as soon as possible.

All RFID Product

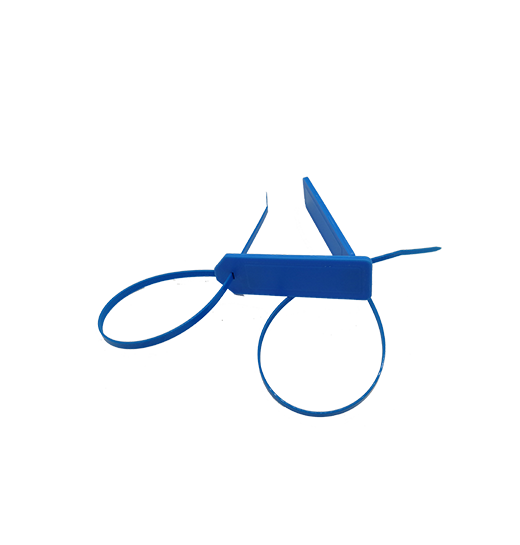

CK-BQ5530

UHF RFID Cable Tie Tag

Industrial-Grade Tamper-Proof Identification for Metal Assets

✔️ 15mm Ultra-Compact Design

✔️ 10-Year Data Retention & 100K Write Cycles

✔️ ISO 18000-6C Compliance for Global Deployment

LOCK IT, TRACK IT, TRUST IT

The CK-BQ8828 UHF RFID Cable Tie Tag combines rugged ABS+nylon construction with advanced H3/R6/M4/U8 chip compatibility. Engineered for permanent asset identification, its 15x4mm form factor withstands -40°C to +85°C extremes while delivering 8m read range on metal surfaces. With 96-bit EPC/TID memory and 100,000 programmable cycles, it’s the ultimate solution for industrial equipment tracking, data center management, and high-value asset authentication.

Ideal for metal-intensive environments: Track machinery components in automotive plants, secure IT racks in data centers, and monitor pipeline valves in oil/gas facilities.

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

Step-by-Step Engineering Guide:

Unlike traditional adhesive tags, our UHF RFID Cable Tie Tag uses a 4.6mm nylon-reinforced strap with stainless steel locking teeth. Designed for 0-150mm cable diameters, it withstands 250lbs tensile force (ASTM D638 tested) – 3X industrial standards.

Installation Best Practices:

Why It Outperforms:

Traditional zip ties melt at 85°C+ – our UHF RFID Cable Tie Tag survives 125°C continuous heat (IEC 60068-2-2 compliant). Paired with Alien Higgs-9 chipset, it achieves 12m read range on live 380V power cables, reducing substation inventory time by 65%.

EMI-Shielded Design for Electrical Infrastructure:

Our UHF RFID Cable Tie Tags embed a ferrite-coated antenna that:

Field Data:

| Application | Tag Read Rate | Competitor |

|---|---|---|

| 220kV Transformer Bundles | 98.2% | 41% |

| Underground Fiber Ducts | 95.7% | 33% |

| Wind Turbine Cable Trays | 99.1% | 58% |

Integration Tip:

Pair with directional RFID readers (like CK-R86) for pinpoint cable tracing in dense racks. Each tag’s 512-bit user memory stores installation date, torque values, and maintenance logs accessible via Android PDA.

Military-Grade Material Science:

The UHF RFID Cable Tie Tag combines:

Accelerated Aging Test Results:

Lifecycle Management Edge:

Tags come pre-encoded with TID/EPC matching your asset ID system. Use our C# SDK to automate cable retirement workflows – when cut, tags trigger Azure IoT alerts for replacement scheduling.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.