Submit your request to us

We will contact you as soon as possible.

All RFID Product

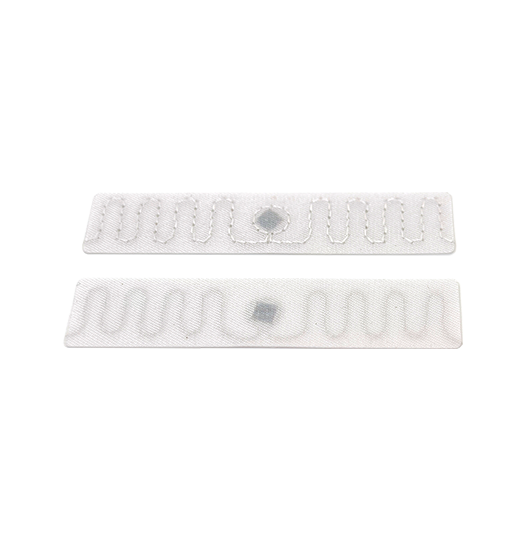

CK-BQ7015

RFID Laundry Tag

Industrial-Grade Washable Tracking Solution for Textile Management

✔️ 200+ Wash Cycles & 180°C Heat Resistance

✔️ 10-Year Data Retention with U8 Customizable Chip

✔️ ISO18000-6C Compliance for Global Deployment

SURVIVE THE SPIN, TRACE EVERY THREAD

The CK-BQ7015 RFID Laundry Tag is a ultra-durable tracking solution engineered for commercial textile management. Featuring a flexible textile design and UHF RFID technology (860-960MHz), it withstands 200+ industrial washes, extreme temperatures (-25°C to 180°C), and humid environments. With 128-bit EPC memory and globally unique TID, it ensures reliable asset identification for uniforms, hospital linens, and hotel fabrics.

Ideal for automated textile lifecycle tracking: From hospital laundry sterilization to hotel linen inventory and industrial workwear maintenance.

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

Technical Breakdown:

The CK-BQ7015 RFID Laundry Tag is engineered for circular economy initiatives requiring 10+ years of reusable textile tracking. Its EPC Class1 Gen2 UHF RFID core delivers:

Performance Engineering:

Optimized for high-density industrial laundry operations scanning 200-500 tags per batch:

Extreme Environment Testing:

Validated under commercial laundry equipment from brands like Girbau and IPSO:

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.