Submit your request to us

We will contact you as soon as possible.

All RFID Product

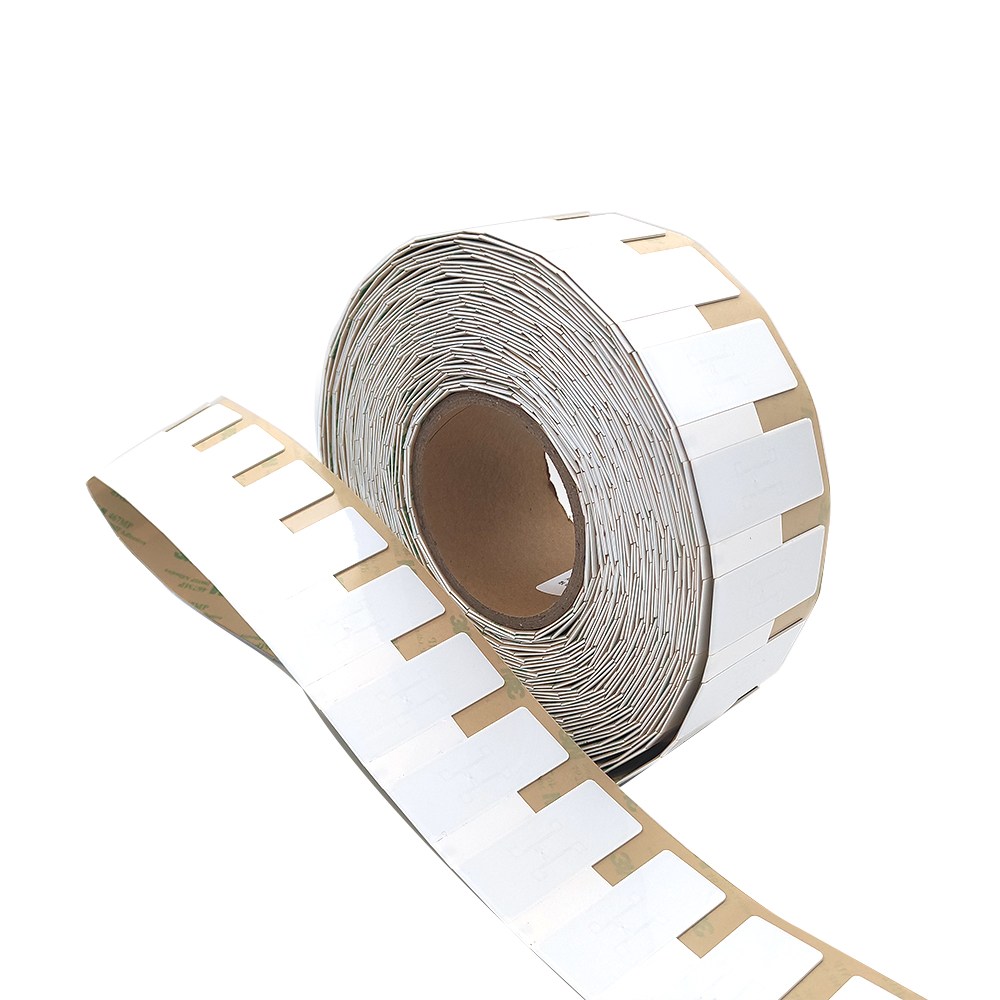

CK-BQ6025

Flexible Anti-Metal RFID Tag

Metal-Surface Optimized RFID Identification for Harsh Industrial Environments

✔️ IP68 Protection & Extreme Temperature Resistance

✔️ 8m+ Read Range on Metallic Surfaces (Lab-Tested)

✔️ IP68 Protection & Extreme Temperature Resistance

METAL DEFIANT, PERFORMANCE RELIANT

The CK-BQ6025 Flexible Anti-Metal RFID Tag is engineered for seamless integration onto metallic surfaces in challenging environments. Featuring an aluminum-etched antenna and IMPINJ Monza R6-P chip, this tag delivers high-speed data transmission (EPC Gen2 compliance) and 100,000+ write cycles. Its PET/foam substrate ensures flexibility and durability, ideal for industrial asset tracking, metal container management, and heavy machinery identification. Operates flawlessly from -40°C to +85°C with 10-year data retention.

Perfect for tracking metal assets in manufacturing, logistics, and construction—from steel pallets to CNC machinery and outdoor metal infrastructure.

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

Traditional RFID tags fail on metal due to signal interference and detuning. The CK-BQ6025 anti-metal RFID tag integrates a PET/foam substrate and etched aluminum antenna to counteract these issues:

Ideal Use Cases:

The CK-BQ6025 is built for industrial extremes, combining IP68 protection and material engineering:

Installation Best Practices:

Yes. The CK-BQ6025 seamlessly integrates with most UHF RFID infrastructure:

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.